The success in automating any stage production arises from mastering four key dimensions: unrestricted safety, high availability, powerful features and an exciting user experience.

Our mission is to provide pure excellence in all dimensions when translating your visions for a spectacular performance into a beautifully choreographed ballet of machine movements.

C⋅A⋅T V5. Powerful. Individual. Safe.

powerful.

Our goal is easily defined: to integrate the best control ideas found in theatre, show and performance automation into a single powerful concept, pushing the existing boundaries.

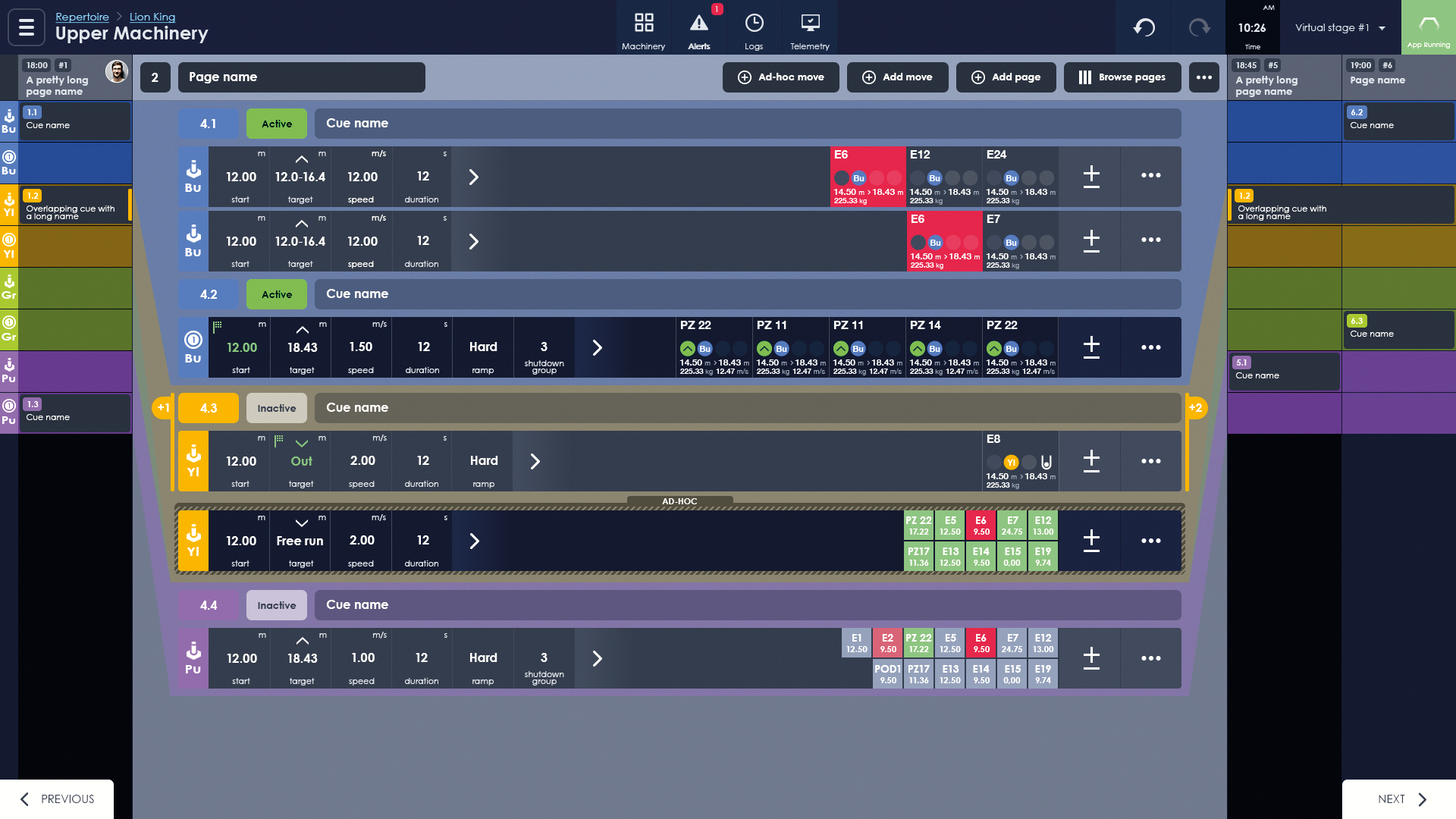

- C⋅A⋅T V5 is designed to realize almost any creative vision by providing a full set of editing and live control features for any kind of machinery driven motion. It offers a full range of control possibilities from directly controlled motion of a single machine for set-up to synchronized group motion with trigger conditions and dynamic effects. Multi-axis 3D motion and communication to external systems are available through modular software upgrades.

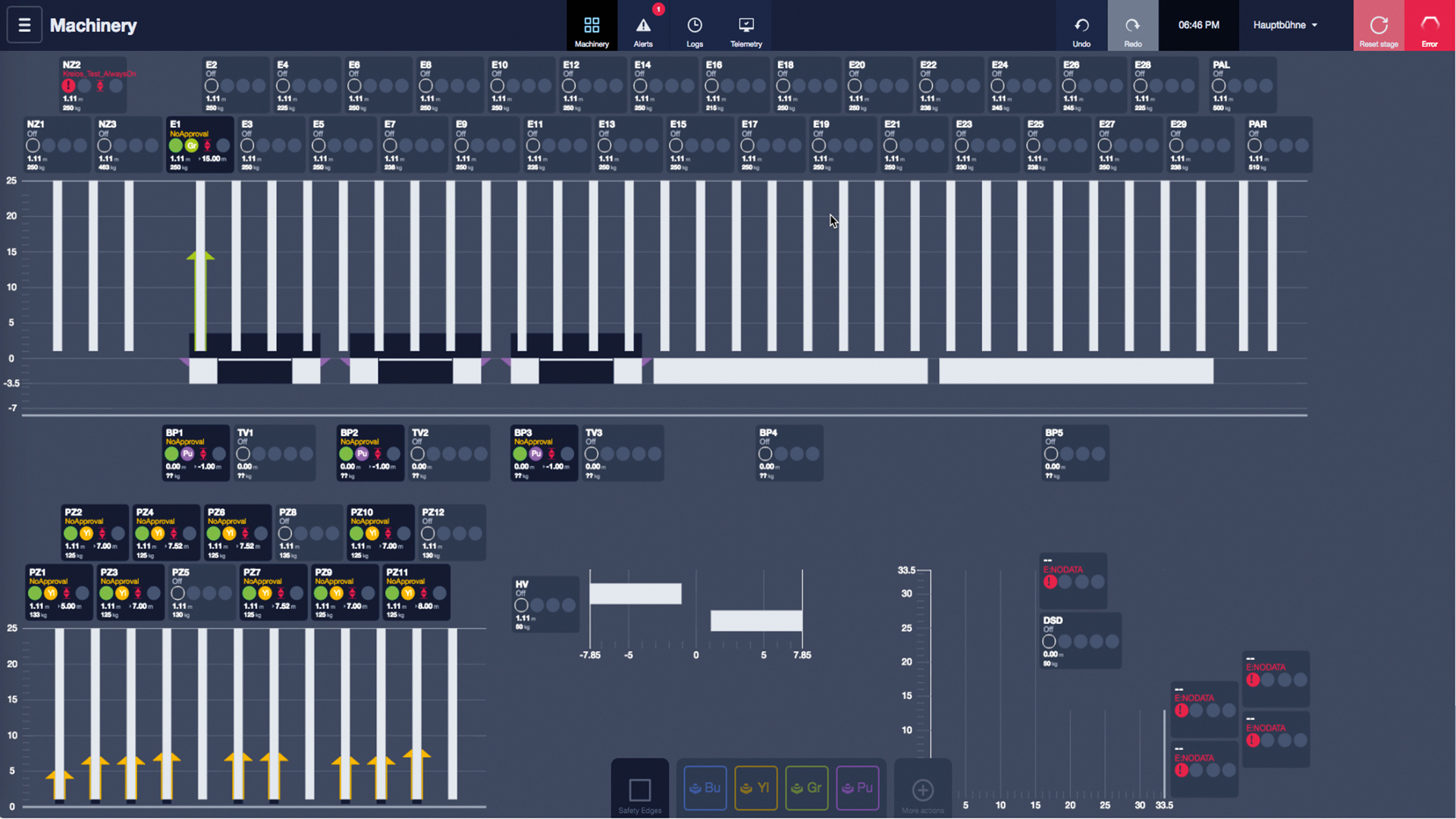

- C⋅A⋅T V5 is designed to enable fully synchronized concurrent moves of more than 200 axes with guaranteed shortest reaction times, even for high-speed performer flying hoists. Its internal equipment modeling engine translates the highly complex mechanical systems into simple and natural operating commands.

- C⋅A⋅T V5 is designed to perform your daily work with minimum effort and produce astonishing effects within a moment. It allows to control and monitor any detail of a motion, and is always quick to respond. Our software solutions do not only focus on live operation of the machinery, but also offer assistance and tools for the entire system life-cycle from installation to operation, trouble-shooting and routine maintenance.

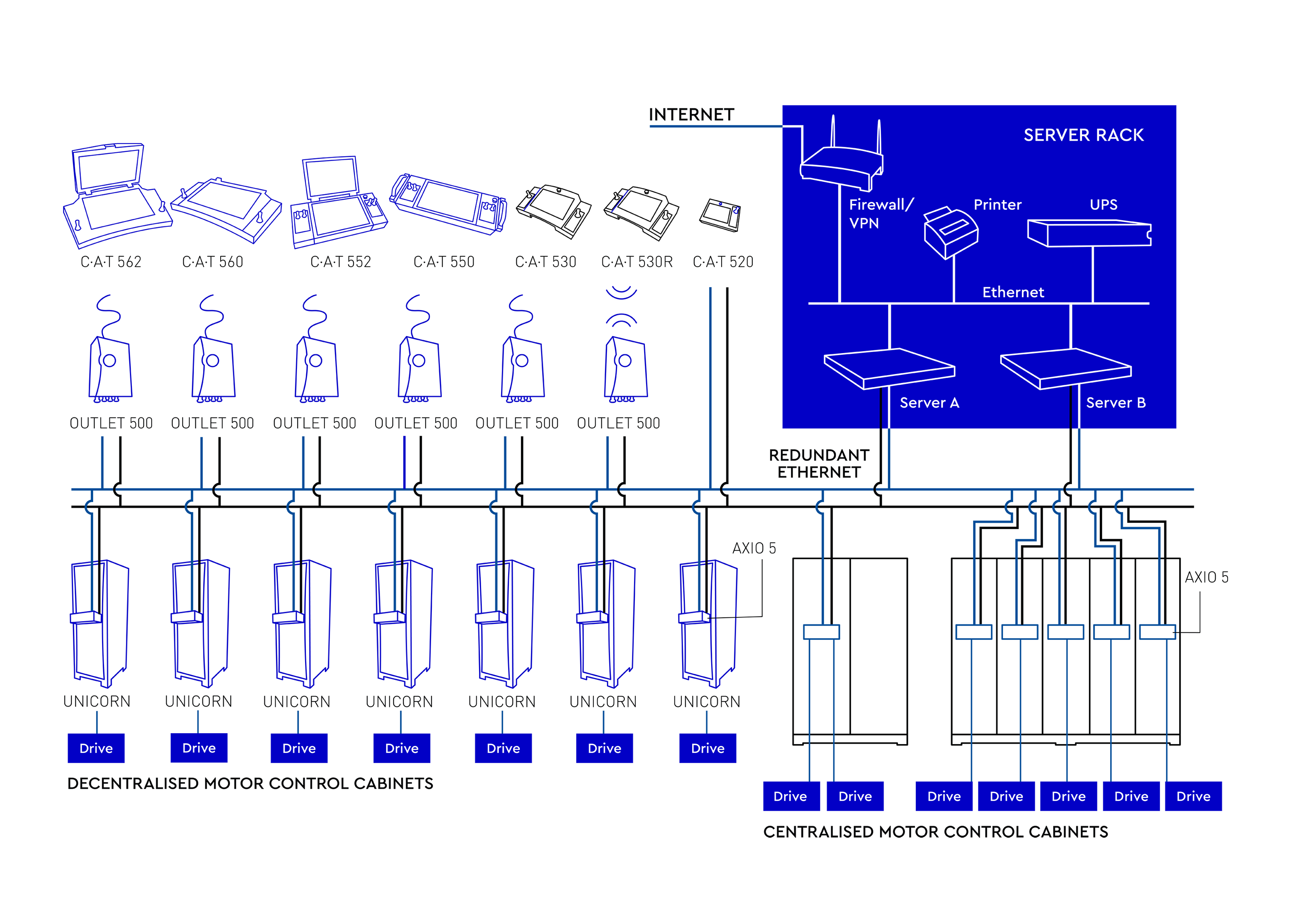

SYSTEM ARCHITECTURE

KEY FEATURES

- The redundant high-speed safety control network can integrate more than 2000 axes into a single control system without loss of timing or precision. It is based on Ethernet technology and uses standard IT network equipment.

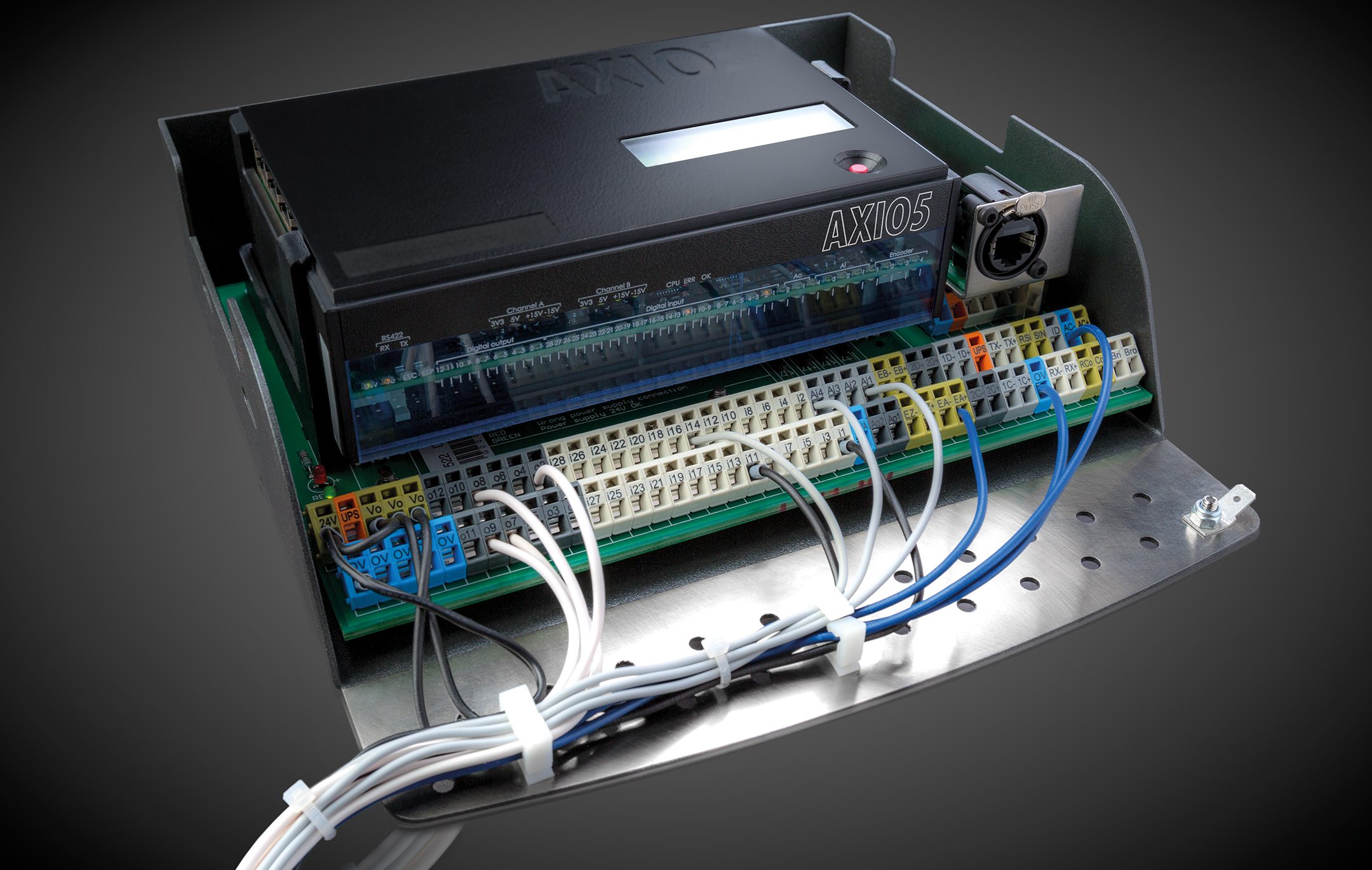

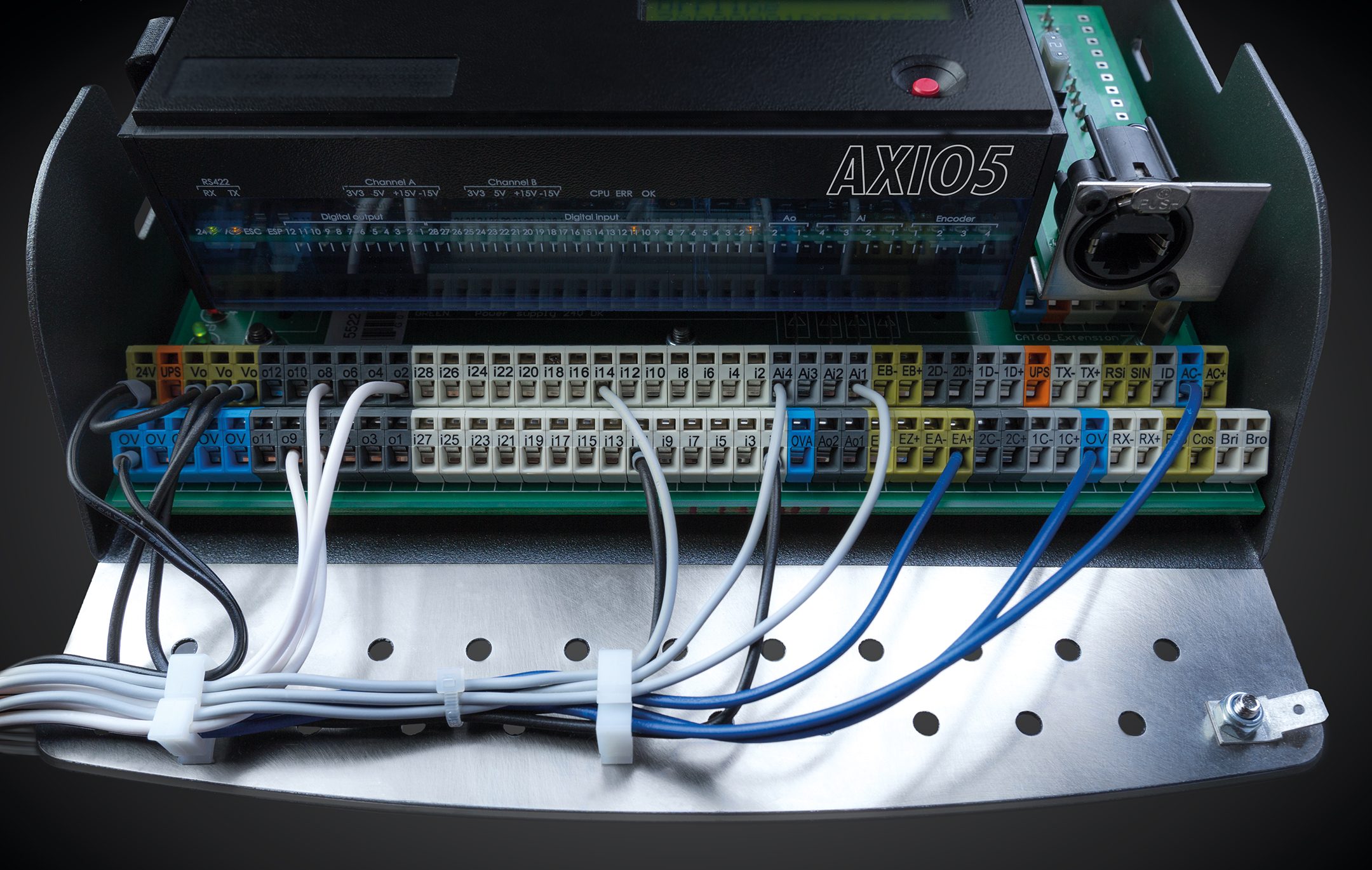

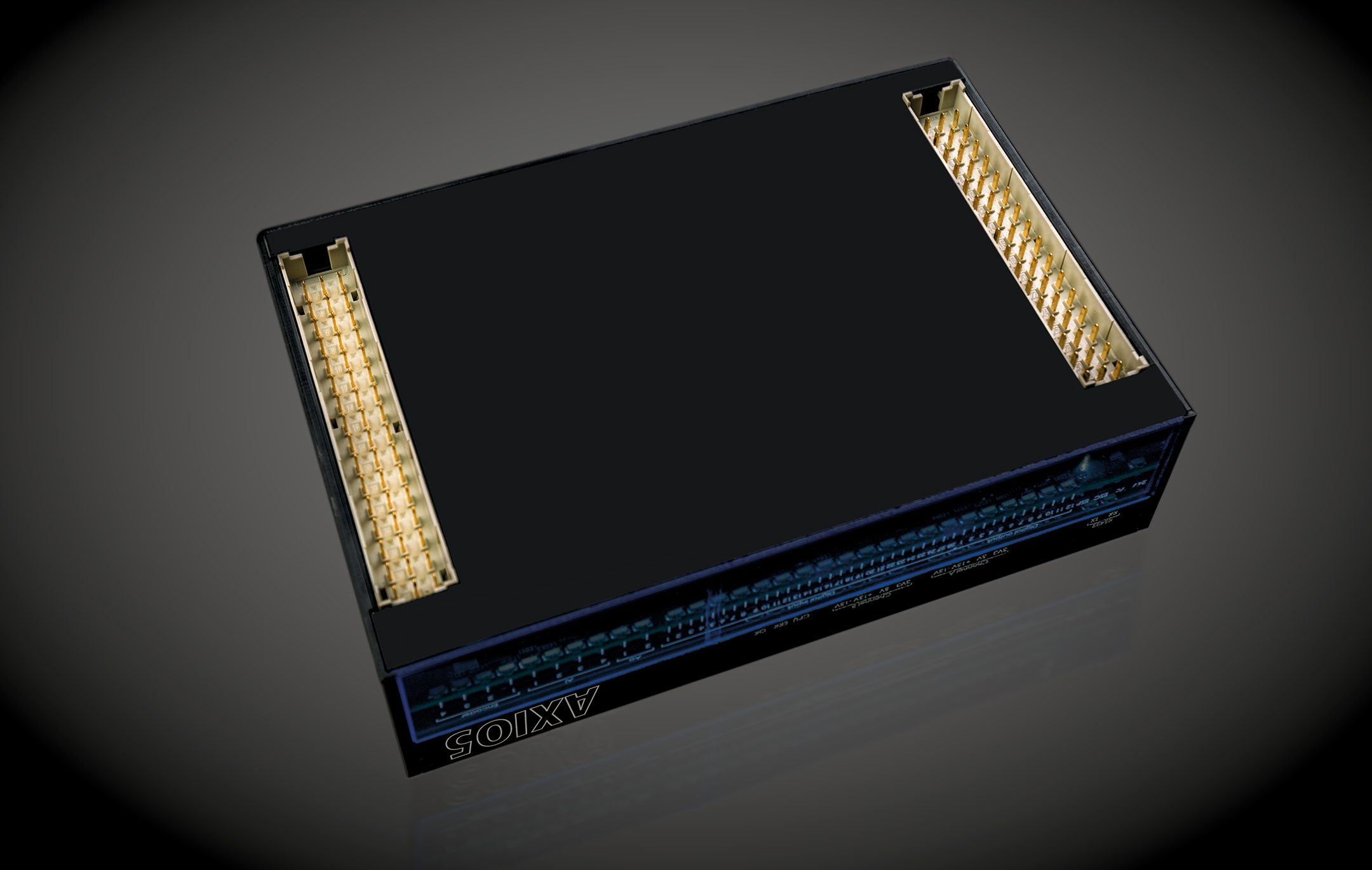

- The AXIO 5 safety motion controller is installed inside centralised or decentralised motor control cabinets. It provides a flexible interface to all kinds and brands of switch gear, variable frequency drives and even hydraulic and pneumatic systems.

- Install UNICORN motor control cabinets next to the machines to realise the shortest commissioning time and benefit from a permanently available plug & play backup solution.

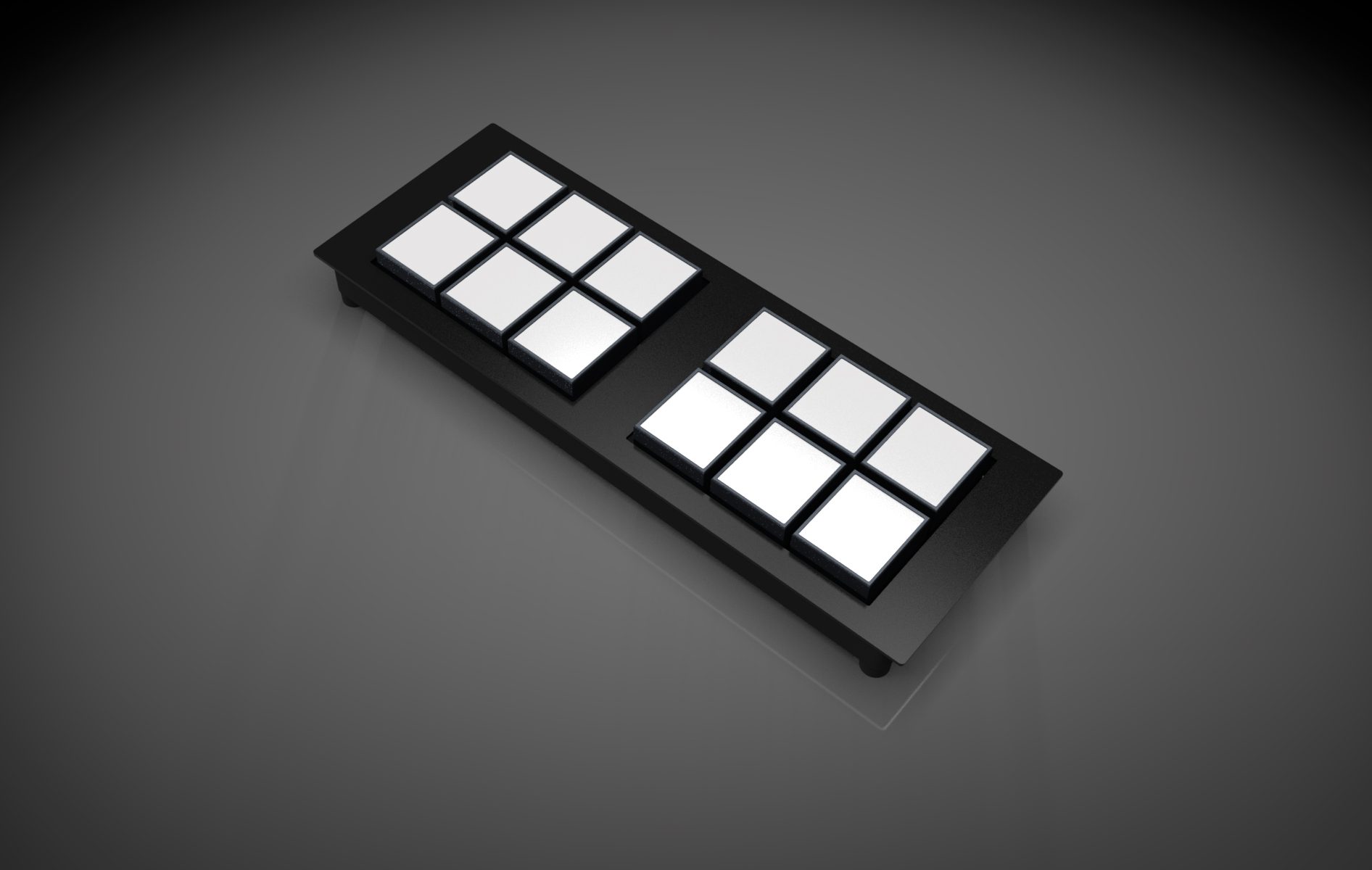

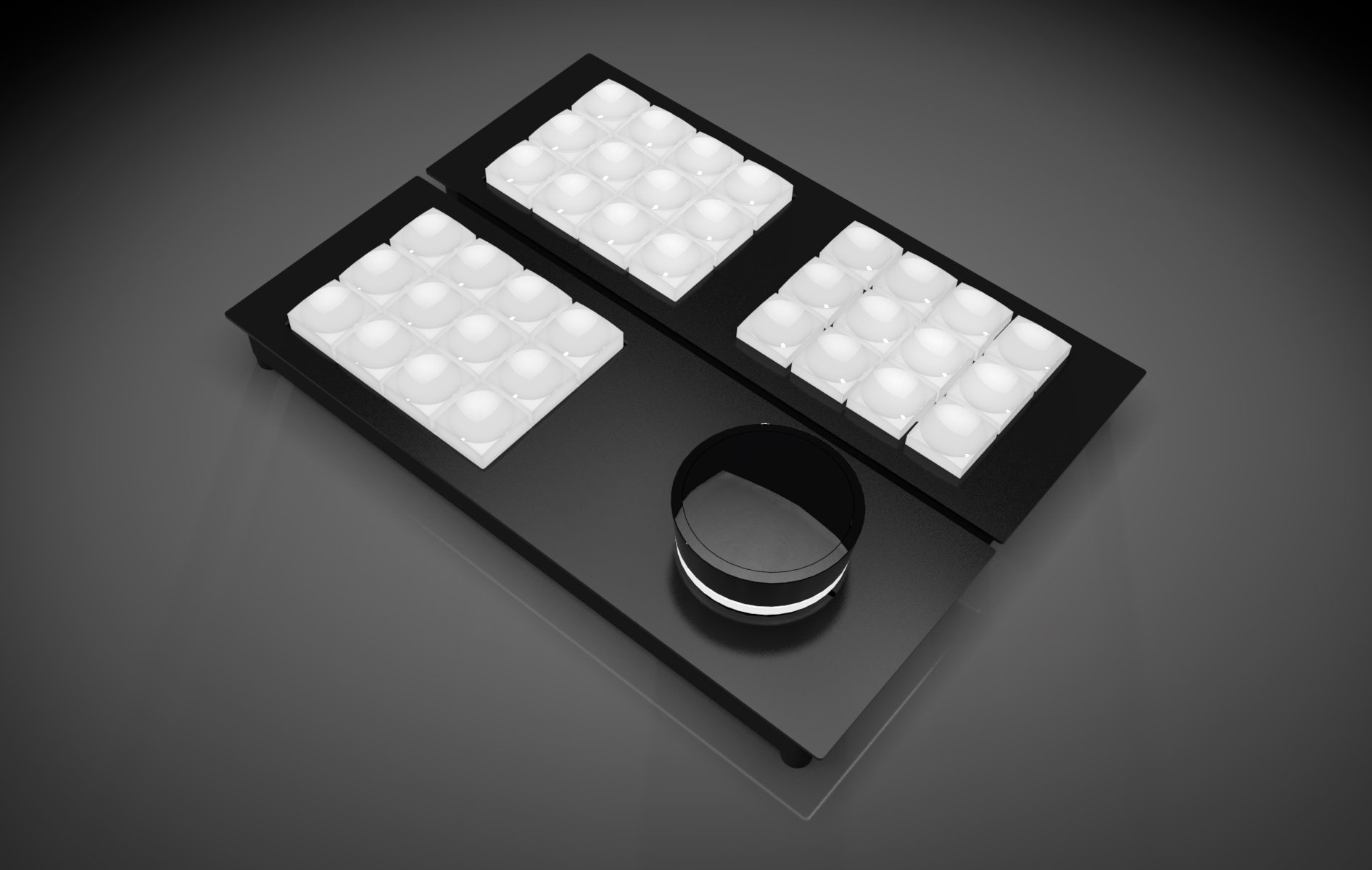

- Integrate up to 30 cable bound or wireless consoles for best possible comfort and safety. Add network connected local control panels and displays where needed.

- Redundant powerful rack server systems integrate data storage and processing for fast user interface response and shortest machine reaction times. The 19” rack server cabinet features a UPS system for control system power protection as well as a third Ethernet network for connecting auxiliary devices.

- A VPN / firewall connection establishes an online link to the C⋅A⋅T remote service and remote backup network through an existing internet connection.

USER EXPERIENCE

SMART GUIDING DESIGN

Best in class user experience composed of

- a well-thought-out visual concept with appealing graphics

- controls design that fully supports the workflow

- a screen layout adapting to the changing working context

- a set of smart assistants that guide you through all challenges in your daily work and

- an integrated collaborative team working environment

was set as target for the C⋅A⋅T V5 user interface.

Participate in the C⋅A⋅T V5 user group for further raising the bar.

HIGHLIGHTS

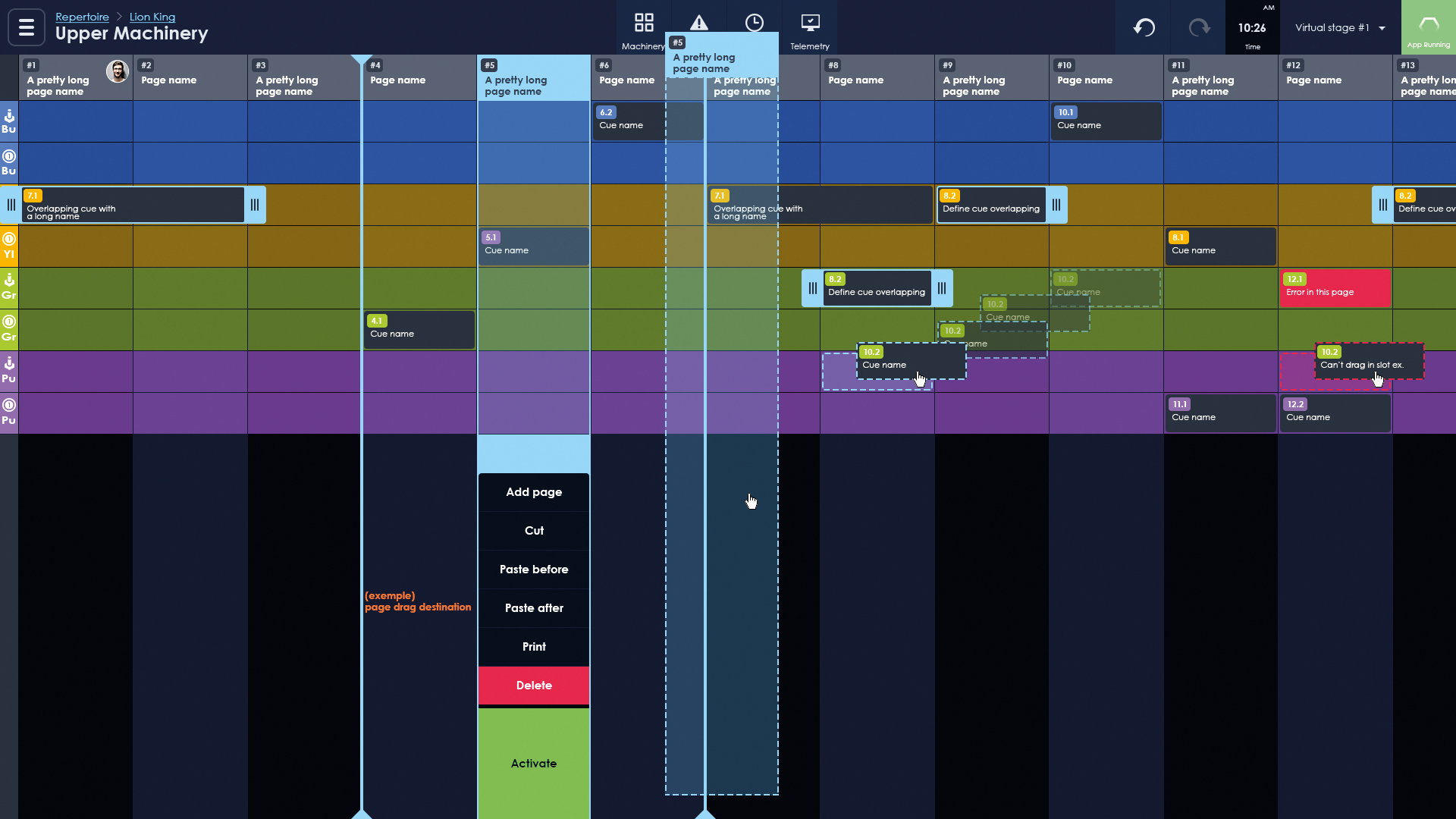

- The modern UI design is inspired by the look & feel of today‘s smart mobile devices. Based on the latest web technologies, the UI remains flexible and adaptable to the fast changing demands of a superior user experience.

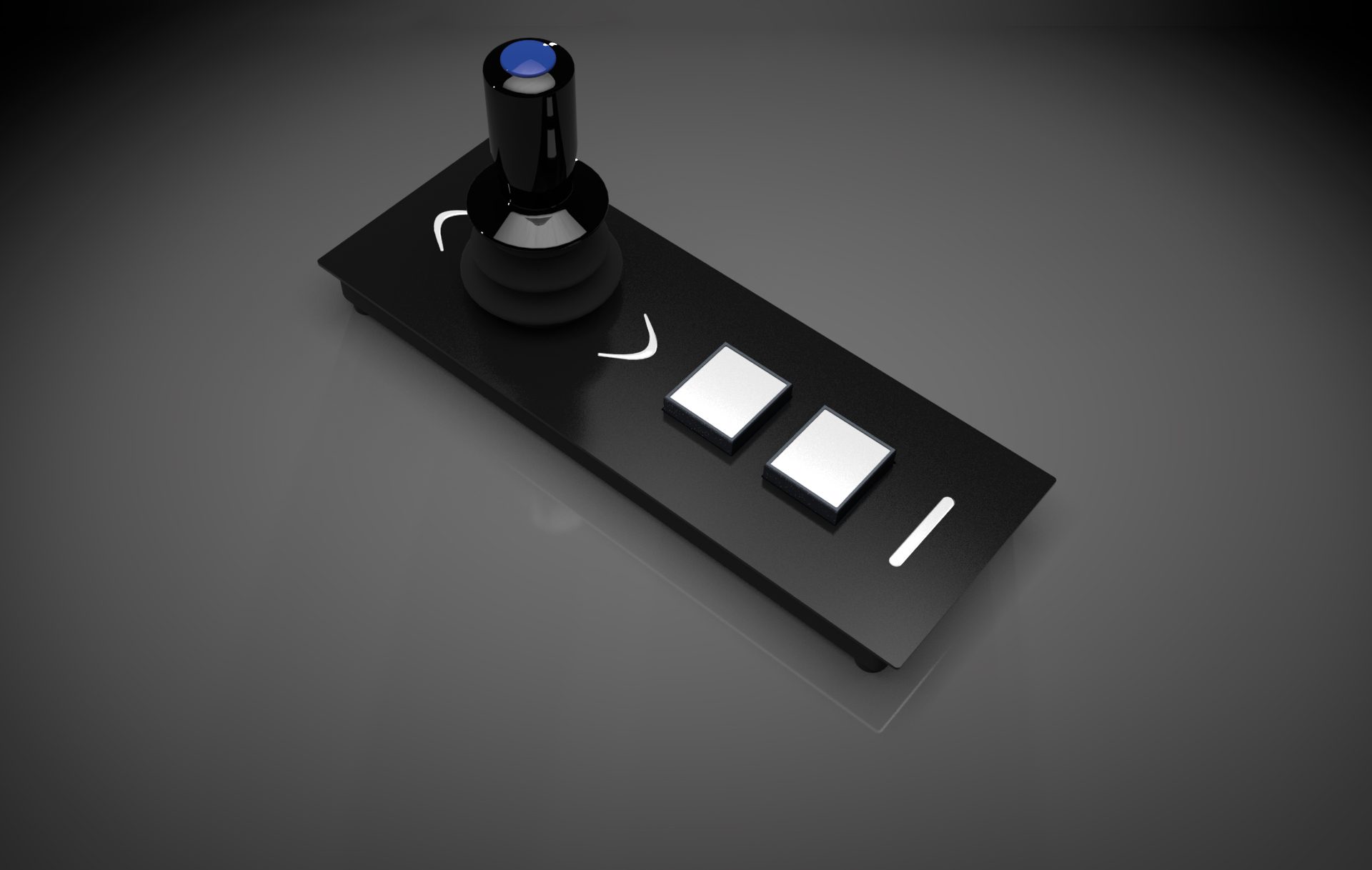

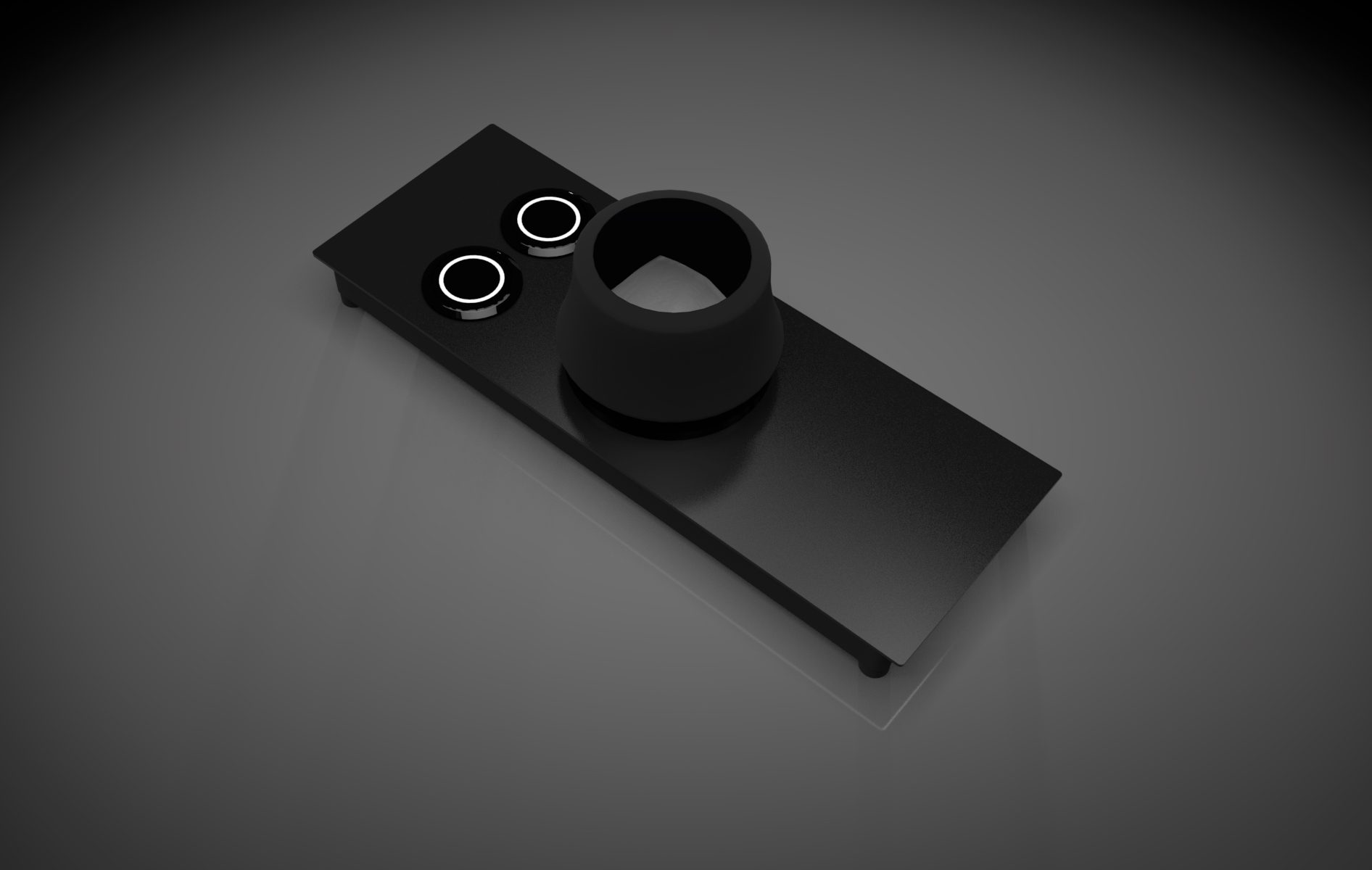

- Support for multi-touch gestures and drag & drop allow for quick navigation and graphical editing on touchscreen consoles. The context sensitive dialogue design enables the intuitive and straightforward operation. And if haptic feedback is essential for you, the C⋅A⋅T GEAR control devices extend the human machine interface from software to integrated hardware options.

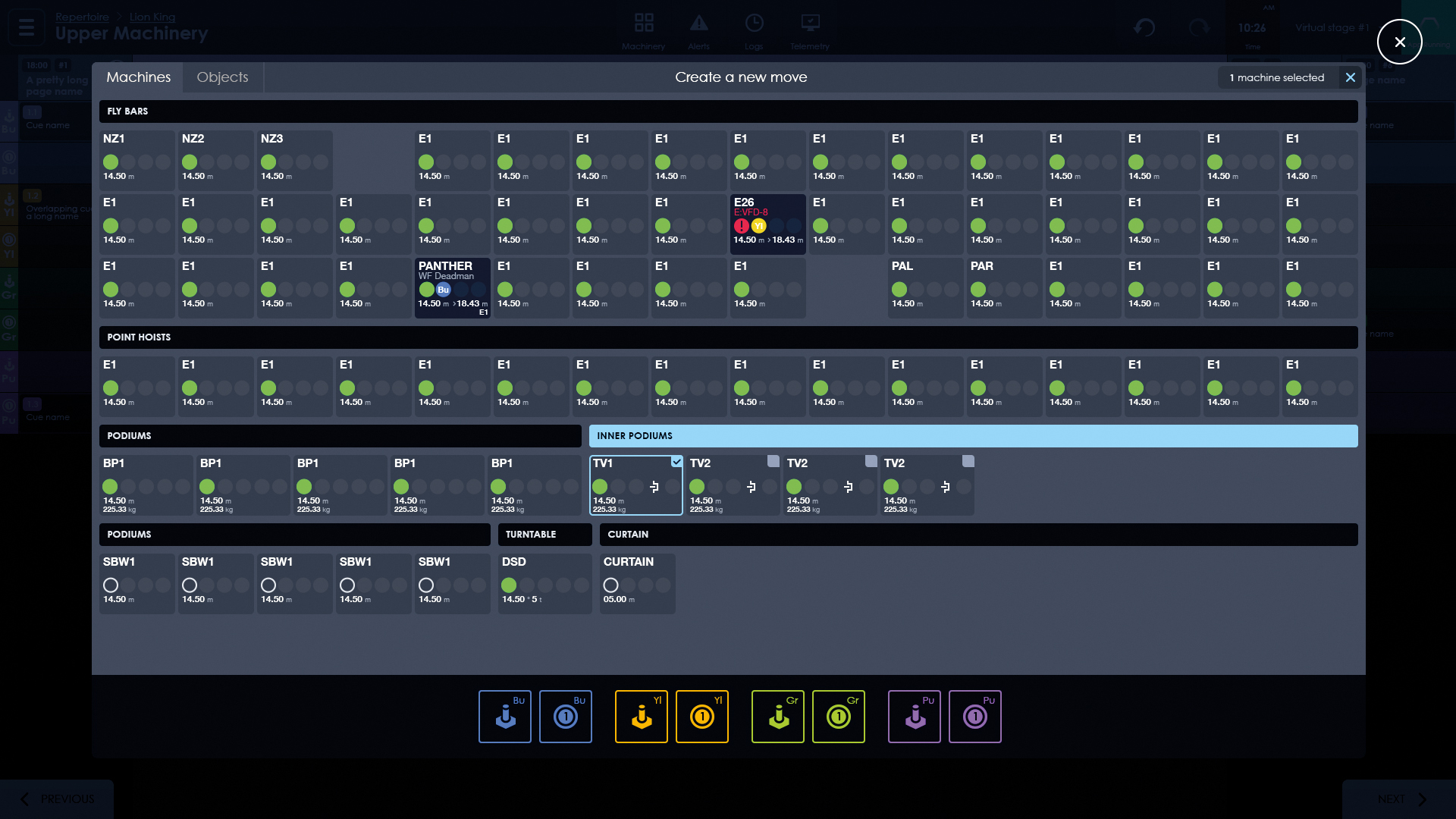

- “Upstage lighting bar down please! We need to refocus.” C⋅A⋅T expects the unexpected. Start any unplanned move within seconds, and without affecting your current programming task.

- Using the repertoire dashboard, you will never again lose track of your show files and archives. Highlight your current favourites for quick access or restore yesterday’s show version from the integrated revision control system.

- Edit and run your shows from the adaptive track-based view while monitoring the system status on the machinery screen. Master even complex shows by mixing down the cues along multiple console tracks. And if a sudden event catches you off guard, simply forward your next cue for execution to another active console.

- Whether you are flying objects from your decoration warehouse or creating a new bare batten ballet: our smart targeting assistant will always suggest the most likely target selections.

- If you need a safe zone for developing the perfect motion profile, choose one of multiple virtual stages for safe move simulation without any risk for the machinery and scenery. Clone your current stage setting to a virtual stage within seconds, and run your cues over and over again. You can share your virtual stage with other operators and practise the most challenging cue sequences from multiple consoles. 3D visualisation of your stage machinery, your decorations or the whole venue will be available at different levels of detail.

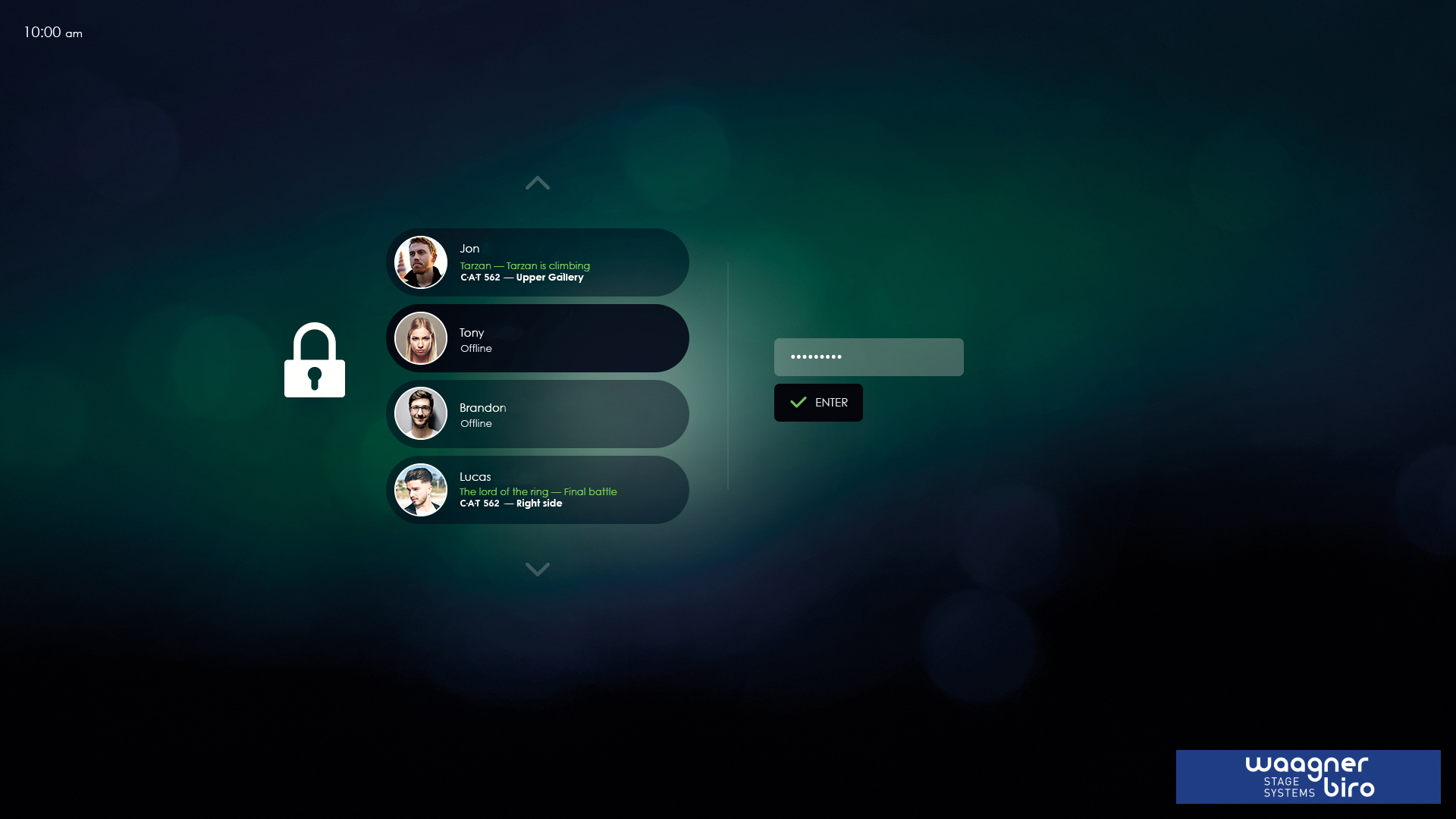

- No matter how many operators are working on different consoles: all your actions are stored in your personal operator session. Restore your previous session upon log in, start a new session or transfer a running session to/from another console when a different location is more convenient or safe. Undo and redo all of your personal actions at any time.

- C⋅A⋅T will turn your technical crews into a collaborative ballet. Based on personalised user accounts, C⋅A⋅T helps you to easily coordinate and follow your team work with the system. Our multi-user editing strategy is designed for full concurrent work without any lock-outs. And because talking is so much more efficient than typing, all C⋅A⋅T consoles feature an integrated high-quality video chat system.

- A built-in graphical telemetry viewer, intelligent alert notifications and human readable logs integrate all necessary tools for maintenance management and trouble-shooting in the operator consoles. The telemetry does not only visualise all relevant i/o and status signals, but links this information directly to user actions and machinery motion, creating an easy to understand visual explanation for all past events.

- The embedded C⋅A⋅T STUDIO is your interface for guided machine setup and configuration management. Automated tools speed up your regular maintenance tasks like brake testing and load sensor recalibration, creating precious time for additional spot maintenance works.

individual.

Any production model in the entertainment industry has its own specific requirements. So too does any individual venue and production, and any individual user role and user.

- C⋅A⋅T V5 is designed with respect to many different ideas and operating concepts. Starting from a widely scalable system design based on cost-effective standard hardware, it offers highly flexible configuration options for both console hardware and control software features. You may find a C⋅A⋅T V5 system as a safety control solution for a single hoist or lift, or as the master automation control system in a large scale acrobatic show.

- C⋅A⋅T V5 is designed with respect to the needs of all the individuals that will find our system in their daily work place. Ergonomics, safety and operation effectiveness – even under stress – are the basis for all our system design decisions. The user interface is designed with focus on optimised workflow, clear visual feedback and smart support of complex operation tasks.

safe.

A consistent and transparent safety concept is our basis for realising integrated machinery control solutions that operate with actors, technicians and audience being in the hazard zone of the machine.

- C⋅A⋅T V5 is developed and certified under EN/IEC 61508:2010 to guarantee a quality level up to SIL 3 / PLe for any implemented safety function. The safety functions are implemented based on the usage scenarios and risk analysis described in the most referenced machinery standards for the entertainment industry EN 17206, DIN 56950-1, DIN 56950-1, CWA 15902-1 and DGUV regulation 17 (former BGV-C1).

- C⋅A⋅T V5 is designed to minimise the risk introduced by operator errors. All editing functions are designed to prevent input of illegal values. Consistency checks will detect conflicts caused by changed system configuration at runtime. Maintenance and failure operating modes are accessible directly in the main operator consoles rather than using a different control device with a different control interface. And finally, the safety functions can be muted selectively to maintain the highest possible safety integrity even when parts of the machinery are defect.

- C⋅A⋅T V5 is designed to provide the highest availability combined with quick and easy to use backup and recovery strategies to minimize the risk for any flying artist or performer.

FUNCTIONAL SAFETY

TRANSPARENT SAFETY

C⋅A⋅T V5 is developed and certified under EN/IEC 61508:2010 to guarantee a quality level up to SIL 3 / PLe for any implemented safety function. The safety functions are implemented based on the usage scenarios and risk analysis described in the most referenced machinery standards for the entertainment industry EN 17206, DIN 56950-1, CWA 15902-1 and DGUV regulation 17 (former BGV-C1).

For any safety function, an individual documentation and safety rating is available.

KEY FEATURES

- Certification according to EN/IEC 61508:2010 p1-7 (2nd edition).

- Type approval according to Machinery Directive 2006/42/EC.

- The AXIO 5 hardware and software is certified as a safety motion i/o controller.

- A certified programming language allows implementation of additional safety functions without recertification.

- The configuration and selection of safety functions is certified.

| Generic safety of machinery |

|

||||||||||||||||||||||||

| Application specific safety functions – lifting and load bearing equipment for the entertainment industry |

|

||||||||||||||||||||||||

| Muting |

|

contact.

Waagner-Biro Luxembourg Stage Systems S.A.

1, rue de l’école

L-4813 Rodange

Luxemburg

Tel: +352 503521

Fax: +352 503524

stagesystems.luxembourg@waagner-biro.com